Rehomy araç arka koltuk düzenleyici, katlanabilir tepsili, poliüretan deri, koltuk arkası koruyucu, piyasadaki araç koltuğu ile uyumlu : Amazon.com.tr: Bebek

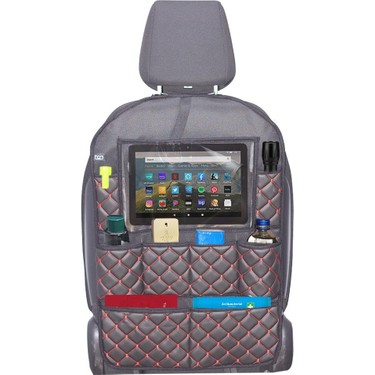

Araba Koltuk arkası organizer,Oto Koltuk arkası düzenleyicileri,Oto koltuk düzenleyici,araba koltuk arkası düzenleyici,Araba organizeri,Koltuk organizeri

Otom Premium Design Deri Koltuk Arkası Araç içi Organizer Eşya Düzenleyici Bej Fiyatı, Yorumları - Trendyol

FSM Auto - Araba Koltuk Arkası Düzenleyici PU Deri 🚘 . .Son 2 adet ❗️ . .Siyah renk stokta kalmadı . .Ürün Fiyatı: 150 TL . . #koltuktakımı #arabakoltukkılıfı #koltukarkası #derikılıf #seyahat #